Key Takeaways

- CNC machining plastic enables the creation of highly precise, complex parts from a wide range of engineering polymers, offering flexibility for industries like automotive, aerospace, and medical devices.

- Commonly machined plastics include ABS, polycarbonate, acrylic, and nylon, each chosen for specific qualities such as strength, clarity, impact resistance, or wear tolerance.

- Key advantages of CNC machining plastic are cost-effectiveness for prototypes and low-volume runs, exceptional tolerances (down to ±0.01 mm), fast turnaround, and the ability to produce intricate geometries.

- Limitations include risk of deformation, thermal sensitivity, tool wear, and material-specific challenges like burring or cracking, requiring expert machining parameters for optimal results.

- Applications span from automotive dashboards and aerospace housings to medical device enclosures and electronics cases, demonstrating versatility across sectors.

- Material selection for CNC machining should consider temperature resistance, mechanical properties, chemical resistance, moisture absorption, and machinability to ensure part performance and durability.

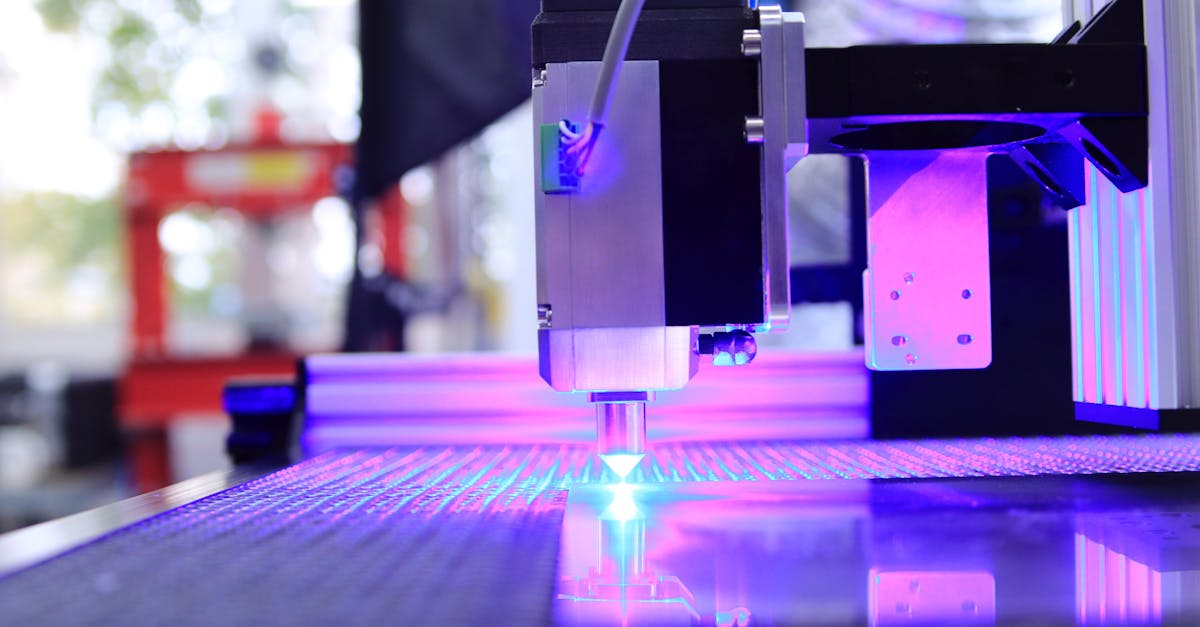

CNC machining plastic utilises computer-controlled tools to shape engineering polymers into highly precise components with tolerances down to ±0.01mm. This versatile manufacturing process supports materials including ABS, polycarbonate, acrylic, and nylon for applications across automotive, aerospace, and medical sectors. CNC Machining technology offers cost-effective solutions for prototypes and low-volume production whilst enabling complex geometries and rapid turnaround times for demanding industrial requirements.

What Is CNC Machining Plastic?

CNC machining plastic uses computer-controlled tools to shape plastic materials with precise movements along multiple axes. Operators load solid plastic stocks like ABS, polycarbonate, POM, or PTFE, then cutting tools trim, bore, or mill the material according to digital CAD models. CNC processes produce accurate, repeatable components for industries needing tight tolerances, including automotive, aerospace, and medical sectors.

Shops like Yijin Hardware in Homestead, FL, apply CNC machining plastic techniques to deliver parts with complex geometries or detailed features. Their services cover prototypes to production runs, supporting projects needing lightweight, durable plastics instead of metals. CNC machines sustain close tolerances down to ±0.01 mm, meeting most industrial quality standards. This approach enables manufacturers to create fast, cost-effective plastic parts without expensive molding tools.

Yijin Hardware uses CNC machining to support applications like housings, insulators, fixtures, and medical device components. CNC-machined plastics offer resistance to chemicals, low weight, and fast turnaround times compared to cast or molded parts. About 90% of standard engineering polymers can be machined on CNC equipment, if the correct tool type, spindle speed, and coolant are selected.

Common Types of Plastics Used in CNC Machining

CNC machining commonly uses four plastics: ABS, polycarbonate, acrylic, and nylon. Each type supports different requirements for strength, clarity, impact resistance, or precision, driving selection for engineering and industrial parts.

ABS

ABS plastic delivers excellent machinability and high impact resistance. Shops like Yijin Hardware use ABS for prototypes and housing components in automotive, medical, and electronics industries. ABS costs less than other engineering plastics and shapes easily with CNC tools, allowing tight tolerances and rapid iterations. Its durability, good thermal stability, and resistance to chemicals make it suitable for casings, instrument panels, and fixture parts. ABS thermoforms easily and withstands significant mechanical stress. This plastic supports high throughput in production runs and provides operators with minimal tool wear, resulting in lower manufacturing costs.

Polycarbonate (PC)

Polycarbonate (PC) provides toughness and high impact resistance for CNC-machined components. Yijin Hardware machines PC for safety enclosures, machine guards, and clear windows in electrical devices. This plastic endures stress without fracturing easily but can form microcracks if machining settings aren’t optimized. Engineers select PC for projects requiring clarity and toughness above standard acrylics. PC also offers electrical insulation, dimensional stability, and heat resistance, supporting demanding applications in industrial, medical, and aerospace assemblies. PC maintains form in both thin and thick sections, expanding its usage for parts that need optical clarity and structural strength.

Acrylic (PMMA)

Acrylic (PMMA) excels at delivering smooth finishes and optical clarity through CNC machining. Applications include display covers, lenses, and signage where transparency and aesthetics matter. PMMA machines easily, maintaining precise edges and uniform surfaces, which benefit from flame polishing or acrylic cement bonding. However, brittleness introduces risk of cracks when exposed to excessive mechanical force or rapid tool paths. Machined acrylic provides cost-effective solutions for prototypes and finished parts with strict optical or dimensional standards, frequently used by shops serving retail, architectural, and laboratory sectors.

Nylon

Nylon supports CNC machining for parts that demand high wear resistance, such as gears, bushings, and bearing housings. Yijin Hardware processes nylon for automotive, textile, and energy equipment components. Nylon absorbs moisture, which can affect part stability and require climate control during manufacturing. This plastic endures repeated cycles, abrasion, and moderate impacts, extending product life in dynamic assemblies. Its self-lubricating properties reduce friction in moving parts, while strong mechanical performance fulfills stringent requirements in assemblies needing consistent performance and longevity.

Advantages of CNC Machining Plastic Components

CNC machining plastic offers precise, cost-effective solutions for part manufacturing across automotive, aerospace, and medical sectors. Industries select CNC processes for plastics like ABS, polycarbonate, acrylic, and nylon when high accuracy, rapid production, or intricate designs are needed.

- Cost-Effective for Prototypes and Small Runs: Manufacturers avoid significant upfront mold costs, making CNC machining plastic components economical for prototypes or small to medium batch production, as demonstrated by firms like Yijin Hardware in Homestead, FL. Compared to injection molding, CNC machining reduces unit cost when order quantities are below high-volume thresholds.

- Exceptional Precision and Tight Tolerances: CNC machines consistently achieve tolerances as tight as ±0.01 mm in plastics, supporting critical applications in medical device casings, aerospace bushings, and automotive mountings. Each component maintains repeatable accuracy across production, ensuring the quality required by high-stakes industries.

- Fast Turnaround on Prototypes: Shops like Yijin Hardware can fabricate functional prototypes from solid plastic stocks within days, not weeks, since mold setup isn’t required. This allows manufacturers to iterate designs without delay, accelerating product development cycles.

- Production of Complex Geometries: Multi-axis CNC capability enables engineers to specify intricate features. Features such as undercuts, sharp internal corners, pockets, and reliefs appear in single setups on parts like custom housings, brackets, and medical components.

- High Surface Quality: Finished parts show smooth surface textures and uniform finishes, supporting both performance and aesthetics. Multi-axis cutting enhances consistency, reducing post-processing needs for optical or sealed components.

- Material Flexibility: CNC machining supports over 90% of engineering polymers, including chemically resistant or heat-resistant plastics that are difficult to mold. Critical parts for laboratory, energy, or food-processing environments benefit from this flexibility.

- Enhanced Durability and Chemical Resistance: CNC-machined plastics, such as PTFE or POM, sustain exposure to harsh chemicals and show long-lasting performance in corrosive or high-wear settings.

- Consistent Quality in Repeated Production: CNC control ensures dimensionally consistent results in repeat batches, aligning with quality assurance standards for volume production.

Businesses in Homestead, FL, can reach Yijin Hardware at +1 626 263 5841 or [email protected] for consultation on precision CNC plastic machining that meets industry-specific requirements.

Limitations and Challenges of CNC Machining Plastics

Plastic parts produced through CNC machining face several material-driven limitations and challenges:

- Deformation and Warping

Thermal expansion and lower modulus of plastics lead to deformation or warping, especially when machining thin-walled or long parts. Cutting forces may cause soft or elastic plastics—such as ABS or nylon—to bend or lose dimensional precision during processing. According to industry sources, these thermal and mechanical factors create tolerance variability not found in metals.

- Heat Sensitivity

Poor thermal conductivity in plastics like polycarbonate or acrylic causes localized heat buildup. Rapid temperature increase can result in melting, burning, or surface discoloration if cooling isn’t actively managed with liquids or compressed air. Improper temperature control can affect part accuracy and lead to cosmetic defects.

- Tool Wear and Gumming

Glass-filled polymers and fiber-reinforced plastics, used for strength or stability, increase cutter abrasion. Plastics prone to gumming—such as POM or soft HDPE—leave residue on tools, reducing machining accuracy and surface quality. Frequent tool replacement or specialized, scratch-resistant tooling extends tool life and maintains consistent results.

- Burring and Cracking

Soft plastics such as PP develop burrs at cut edges that need additional finishing. Brittle plastics, including acrylics, may chip or crack at corners or thin features, requiring careful tool path and cutter choice to prevent part rejection.

- Material Restrictions

Some soft plastics deform too easily and some brittle plastics fracture under standard CNC forces. Materials with low machinability might need alternative cutting methods—such as waterjet or laser—to achieve acceptable quality. Only about 90% of standard engineering polymers are suitable for CNC processes when using proper tooling.

Experienced providers like Yijin Hardware in Homestead, FL, optimize machining parameters for each plastic grade, combining application expertise with advanced equipment to minimize these challenges in automotive, aerospace, and medical components.

Applications of CNC Machined Plastic Parts

Automotive companies use CNC machined plastics for dashboards, handles, lighting covers, and housings. These components meet strict quality standards for both prototypes and end-use parts in interior and exterior assemblies.

Aerospace suppliers use CNC machined thermosetting polyimide and similar plastics for valves, pump housings, and load-bearing structural supports. These plastic components resist corrosion and withstand high temperatures where metal replacement is essential for weight reduction.

Medical manufacturers produce electronic enclosures for pacemakers, surgical instruments, and durable implant components using CNC machined, wear-resistant plastics. Common applications include precision-fit housings and bio-compatible device parts.

Electronics makers create cases and shells for TVs, laptops, and smartphones from CNC machined plastics. The process enables intricate designs, precise dimensional stability, and reliable performance for high-volume consumer goods.

Industrial and agricultural businesses rely on CNC machined pulleys, levers, irrigation parts, protective covers, and machine components. These parts offer chemical resistance, customization, and long-term durability.

Oil and gas companies specify CNC machined plastic seals, connector housings, and chemical-resistant containers for harsh environments, where metal parts can corrode.

Food processing suppliers use CNC machined plastic trays, guides, and packaging containers for impact resistance and food-safe storage or transport.

Specialized engineering uses include precision gears, low-friction bearings from POM (Delrin), and prosthetic parts made from recycled polypropylene, providing tight tolerances and reliable mechanical performance.

Yijin Hardware in Homestead, FL supplies CNC machined plastic components for these sectors, pairing local expertise with high-precision custom manufacturing.

Factors to Consider When Choosing a Plastic for CNC Machining

Selecting the right plastic for CNC machining depends on performance requirements and the intended application of the part.

- Temperature Resistance: Plastics like PEEK and PTFE remain stable above 250°C, making them suitable for high-temperature environments. ABS and polycarbonate perform well at lower temperatures, while POM melts at around 165°C, so it’s unsuitable where heat exposure exceeds this.

- Mechanical Strength and Hardness: High-strength choices like PEEK and polycarbonate provide durability under heavy loads. POM and ABS offer good machinability for moderate strength needs, while low-rigidity plastics such as polypropylene and PMMA may gouge during machining if not handled properly.

- Chemical Resistance: PTFE and PVC withstand aggressive chemical environments, and HDPE also resists chemicals while maintaining machinability. These characteristics make them common in industrial parts exposed to corrosive agents.

- Moisture Absorption: POM absorbs little moisture, keeping dimensional stability in wet settings. Nylon has high moisture absorption, so it’s not recommended when exposure to water or humidity could compromise accuracy.

- Machinability and Application-Specific Properties: POM is chosen for gears and bearings requiring stiffness and dimensional control. Polycarbonate serves in impact-resistant roles such as safety shields, and selection relies on balancing ease of machining with functional demands.

For businesses in Homestead, FL, Yijin Hardware supports selection and machining of plastics like PEEK, ABS, PTFE, and HDPE, aligning material properties and precision production for sectors including automotive and aerospace.

About Yijin Hardware

Yijin Hardware, located in Homestead, FL, is a leading provider of precision manufacturing services, specialising in CNC machining, sheet metal fabrication, and custom fasteners.

Under the leadership of CEO Gavin Yi, Yijin Hardware also offers additional solutions such as die casting, injection molding, and 3D printing to support various industries, including automotive, aerospace, medical, and energy. With a commitment to high-quality manufacturing and precision engineering, Yijin Hardware delivers tailored solutions to meet the unique needs of its clients.

Contact:

Gavin Yi, CEO

Phone: +1 626 263 5841

Email: [email protected]

Website: www.yijinsolution.com

Location:

760 NW 10th Ave, Homestead, FL 33030

Frequently Asked Questions

What is CNC machining for plastic parts?

CNC machining for plastic parts uses computer-controlled machines to cut, shape, and finish solid plastic materials according to precise digital designs, producing accurate and repeatable components for various industries.

Which types of plastics are commonly CNC machined?

Common plastics machined via CNC include ABS, polycarbonate, acrylic, and nylon. Each offers unique properties suited to specific engineering and industrial needs, such as strength, clarity, or wear resistance.

Why choose CNC machining for plastic components?

CNC machining offers cost-effective production, tight tolerances (down to ±0.01 mm), rapid turnaround, and the flexibility to produce complex shapes in both prototypes and end-use parts.

What industries benefit from CNC machined plastic parts?

Industries like automotive, aerospace, medical, electronics, industrial equipment, agriculture, and food processing all benefit from CNC machined plastic parts due to their durability, precision, and adaptability.

What are the main advantages of CNC machining plastics over metals?

Plastics are lighter, corrosion-resistant, and often cost less than metals. CNC machining allows precise shaping of plastics, producing durable, high-quality parts suited for specific industrial needs.

What potential challenges exist in CNC machining plastics?

Challenges include plastic deformation from heat, risk of warping, tool wear, and possible burring or cracking. Experienced providers optimize machining settings to minimize these issues.

How do manufacturers select the right plastic for CNC machining?

They consider factors like temperature resistance, mechanical strength, chemical resistance, moisture absorption, and how easily the plastic can be machined for the intended application.

Are CNC machined plastic parts suitable for harsh environments?

Yes, many engineering plastics—like PTFE and PEEK—can withstand harsh environments, including high temperatures, chemicals, and moisture, making them ideal for demanding applications.

Can CNC machining handle small and large production runs?

Absolutely. CNC machining is suitable for both prototyping (small runs) and larger production batches, offering consistent quality and cost-effectiveness without expensive molding tools.

Where can I find CNC plastic machining services in Homestead, FL?

Yijin Hardware in Homestead, FL, provides precision CNC machining for plastics, supporting various industries with custom solutions, material selection, and strict quality standards.